Reliability of our grids

In spite of COVID-19, work in our failure response procedure largely continued in 2020. With safety as a high priority and undertaking a proactive approach, our professionals set to work outdoors and in homes, sometimes at customers with confirmed or suspected COVID-19. Our fitters are provided with additional personal protective equipment (PPE) for these situations, thereby guaranteeing the health and safety of fitters as well as customers.

On average, customers were not supplied with electricity for 25.73 minutes in 2020 – a deterioration compared with 2019, and almost 9 minutes more than the target. The deterioration is due almost entirely to a complex and lengthy failure in The Hague in August 2020. Without this failure, customers would have been without electricity for an average of 19.12 minutes.

The average downtime for gas was 26.4 seconds. Our target was 30 seconds. This is a significant improvement compared with 2019.

Annual average downtime for electricity (in minutes)

The average downtime for electricity and gas in the Netherlands will be made known after the date of publication of this annual report. We will publish these Dutch averages on our website as soon as the figures are known.

Causes of downtime for electricity (in per cent)

Annual average downtime for gas (in seconds)

Causes of downtime for gas (in per cent)

Supply reliability (in per cent)

A service engineer at the home of a customer with COVID-19

Failures – their causes and what we do to prevent them

It is our objective to use the materials in our electricity and gas grids as long as possible in order to keep the societal costs for the energy supply at a minimum. It goes without saying that safety and reliability are the highest priority at all times. In this section, we discuss the causes of failures in 2020, highlighting those that had the severest impact. We also explain what we do, through maintenance and replacement, by way of effective and smart failure prevention.

Ageing grids

Our policy of risk-based replacement, whereby we utilise the technical service life of assets and only replace what is absolutely necessary, means that the average age of the Stedin grid is increasing. Despite having had relatively few failures in recent years, Stedin nonetheless recorded increased downtime this year due to an exceptional incident. Our aim of maintaining the safety and quality of the existing grids means we need to continually invest. Not just by replacing parts of the energy infrastructure, but also by making them smarter. That way, we can use the data that this generates to determine our replacement capital expenditure even more accurately. In 2020, for example, Stedin installed 1,600 Smart Grid Terminals in 800 stations.

Excavation activities

Disruptions are often caused by excavation activities. The volume of excavation activities has increased for several years, rising by 13.5% in 2020 (2019: 11%). This increase also leads to more excavation damage, resulting in a higher incidence of related disruptions. The growth in excavation activities is partly attributable to increased construction work in our coverage area. Roughly a quarter of excavation damage was the result of work to lay fibre-optic cables.

The 'CROW 500' guideline, which was drawn up in order to prevent avoidable excavation damage, continues to be poorly observed. The Ministry of Economic Affairs and Climate Policy and the regulator Radiocommunications Agency Netherlands have given the parties concerned until 1 January 2022 to comply with the guidelines. The Cable and Pipeline Consultative Body (Kabel en Leiding Overleg), of which all the grid managers are members, has launched a programme to ensure this is achieved.

The 'Dig safe' campaign, which we launched in 2019 together with the other grid mangers, was continued in 2020. The campaign had a positive effect, with the number of recorded instances of excavation damage among consumers decreasing by more than 10% in the spring. In addition, Liander, Stedin and Enexis signed an agreement with KPN NetwerkNL in 2020 to work together in order to avoid cable damage during excavation work for the fibre-optic network.

Power outage with significant impact in 2020

A power outage in The Hague in August left 37,000 customers without power. Short-circuiting occurred in the main distribution station at De Constant Rebecqueplein, caused by a defective power supply bushing in the ceiling between the second and third floors. The short-circuiting triggered the automatic protection device in the station, disconnecting the power in the entire station. The area affected covered the centre and the west of the city. This took place in the morning. Power was restored to a small number of customers in the centre in the afternoon by switching over to other parts of the grid. The remaining work to restore power had to be undertaken by employees in the main distribution station itself. Because of thick smoke, they were unable to enter the building until after the fire service had ventilated it and given the all clear. Once inside, they quickly established that the high-voltage rail was damaged. In the interest of safety, it was decided not to reconnect the power until the rail had first been thoroughly cleaned and measured. Around 6:30 p.m., the rail passed the final inspection and was taken back into operation. Power was restored to the final customers around 7:00 p.m. All the customers affected who were without power for more than four hours are entitled to compensation from us for the outage. The compensation package amounts to roughly €1.6 million.

Maintenance and replacement

Smart, risk-based maintenance

In 2020, we moved data-driven, risk-based maintenance onto a new plane. This involves us using data to pinpoint where maintenance is really needed, where it is not essential and which assets need replacing. In addition to quality improvements, this yields significant annual grid-related savings while also improving safety. More information is also available for less effort. In addition, the results of the various models are easier to visualise in our geographic information system. This system ensures that the data are widely accessible across Stedin.

Accelerated replacement of grey cast iron pipes

Following a gas explosion in The Hague in 2019, the State Supervision of Mines (SodM) carried out an investigation and made several recommendations. The State Supervision of Mines called for an acceleration of the existing remediation programme for grey cast iron gas pipes and asbestos cement by the grid managers. Stedin has brought forward the deadline for the accelerated replacement of its grey cast iron gas pipes from 2030 to 2028. A total of 150 km of grey cast iron pipes were due to be replaced in 2020. Due to the impact of the COVID-19 crisis, the replacement schedule was not met and only 139 km of pipes were replaced. The shortfall will be made up in 2021 and has no impact on the deadline that has been set. All grey cast iron pipes will now also be inspected yearly end-to-end for possible leaks.

Using data for maintenance:

- We have approximately 11,600 smart switch systems in our grids. We carry out risk-based maintenance using data obtained from analyses. In addition to improving the effectiveness of maintenance procedures, this has also resulted in annual cost savings of 12%.

- The medium-voltage grid includes 23,000 connections, consisting of 15,550 km of cable and 96,000 connectors between cables and pipes. Whereas the condition of these assets used to be assessed on the basis of a limited number of indicators, such as age, this is now done on the basis of just 10 indicators, including local environmental conditions. As a result, we only need to replace 140 km of cable each year instead of 200 km. The next step is to determine whether the connections are actually in bad condition. To do this, we carry out measurements for the leading 250 potentially poorest connections. In this way, we can detect hotspots that really need replacing. As a result, we will need to replace 40 to 65 km of cable instead of the 140 km previously planned.

- Stedin and Liander have jointly further developed the model for the replacement of gas pipelines. The leading causes of failures are excavation damage and ageing in combination with environmental conditions. We successfully developed a model at asset level for predicting the likelihood and risk of gas pipeline failure. This model provides important input for risk assessment and hence for maintenance and investment planning.

The coronavirus crisis enables accelerated replacement of cast iron gas mains in Rotterdam

Digging up the street to replace 130 metres of cast iron gas mains at Stadhuisplein in Rotterdam is no easy task between hordes of shoppers and outdoor seating areas that would normally be busy. But in this case, the coronavirus crisis gave us an opportunity.

The municipality of Rotterdam gave approval for the work to go ahead, and the owners of the hospitality venues also enthusiastically helped to clear the terraces. The work in Rotterdam has now been completed.

Replacement of mini-terminal boxes

Each year, we analyse failure trends. This can lead to adjustments in maintenance policy and/or other choices for investments in our grids. Our people then work with our analysts to find a practical solution. An example is the replacement of 'mini-terminal boxes' ('dwergeindsluitingen'), a specific type of terminal box that is widely used in the Delfland area. They use grease as an insulation medium, which can cause short-circuiting if it leaks. It was observed in the field that this caused a relatively high number of failures, prompting calls to examine suitable alternatives. Repeated failures highlighted the need to prioritise this issue. We are now in the process of replacing 135 terminal boxes. This should result in fewer failures in medium-voltage installations, which can cause serious damage.

Increasingly smarter deployment of service engineers

Our service engineers do more than just remedy failures; they also carry out maintenance on our energy grids. Smarter planning enables us to increasingly deploy our fitters for the construction and replacement of parts of our grid, alongside their maintenance activities. This work, which is carried out to a high technical standard, allows us to maintain and develop the qualities of our technicians, which in turn is useful when dealing with failures.

High-voltage projects

Stedin is involved in a large number of projects related to high voltage. More solar farms have been connected and high-voltage stations modified to transport the energy that is generated from decentralised locations. We have also begun the necessary preparations for the connection enabling CO2 reduction through storage beneath the North Sea (Porthos), for example. Another large project is the reconstruction of a dyke strengthening programme in Krimpenerwaard. In order to ensure the interests of the water authority, Oasen, Stedin and the municipality remain closely aligned, we have entered into a cooperation agreement. In 2020, significant progress was made for environmental management and the preparation of the call for tenders.

High voltage on Energy Island

Middelharnis, or 'Energy Island', as it is also known, is a major hub for renewable energy generation. The capacity of the wind farms there is projected to be roughly 225 MW at the start of 2022. There are also several large-scale and small-scale solar farms, with a capacity of approximately 200 MW.

In order to cope with these vast amounts of electricity, Stedin began work on a major expansion of the high-voltage station in Middelharnis in 2010. Four large transformers and four new 50 kV switching installations have been constructed in phases. Two 150 kV connections have also been laid to the Rotterdam port area. These two additional connections are needed in case of an overcapacity of electricity generation on sunny and windy days. This overcapacity of electricity will then be routed to the Rotterdam port area. Such overcapacity of electricity generation is easily reached, when one considers that the power consumption of Middelharnis itself (on days without any sun or wind) is a maximum of 35 MW.

The penultimate phase of this investment in the grid will be completed in 2021. The last phase will be completed by mid-2023.

Investments in our grids

Our investment levels have increased year on year since 2017. In 2020, we invested a total of €620 million, of which €613 million was invested in our regulated grids. Total investments were consequently €26 million lower than in 2019, at 93% of what was planned for 2020. Growth slowing down in 2020 was largely attributable to the coronavirus crisis. This had a negative impact on the planned grid-driven investments as well as our investments in smart meters.

As part of the five-year efficiency programme, we were able, by improving our work efficiency and making our investments more risk-based, among other things, to achieve a saving of more than €10 million as well as €3 million in one-off savings in 2020.

Customer-driven investments

Customer-driven investments in 2020 amounted to €272 million: €12 million higher than budgeted and €18 million more than in 2019. These are the investments we make at the request of customers. Investments remained high in all areas, such as the high volume of new home buildings, the growth in the field of improved sustainability (charging point connections, solar farms, etc.) and the increase in terms of public authority-driven reconstructions. It is our expectation that the customer-driven investments will remain substantial in the coming years, increasingly driven by the pace of the energy transition. At the same time, COVID-19 has led to increased social and economic uncertainty. This trend, taken as a whole, makes planning and adjusting investments more challenging and even more important than in the past.

Grid-driven investments

Our grid-driven investments in 2020 were €276 million. This is €39 million less than budgeted and €18 million more than in 2019. The planned grid investments were hit by delay as a result of the COVID-19 crisis. Grid-driven investments are the investments that are made to guarantee and improve the capacity and quality of the existing grid.

Regarding gas replacements, more than 21,968 primary gas connections (target: 23,000), 97 NEN 1059 control stations (target: 117) and over 139 kilometres of cast iron pipelines (target: 150 km of pipelines) were nonetheless replaced.

We partly attained our target as regards electricity replacements through the replacement of 76 COQ/MIPAK stations (target: 86). Remediation work at customers' homes was delayed due to COVID-19. In addition, we decided proactively to put off investments in the light of evolving customer demand, which is not expected to have an impact on our network for the time being.

Smart meters

Our investments in smart meters in 2020 were €48 million, which is €19 million less than budgeted. Smart meters was where we saw the most direct impact from COVID-19, due to the decision to suspend work at customers' homes early on in the crisis. The long-term target for 80% of all households to have a smart meter by the end of 2020 was nonetheless achieved in part of our service area. It is expected that we will have installed smart meters in more than 80% of homes across our entire service area by the first half of 2021. You can read more about this topic in 'High-quality products and services'.

Other assets

The other investments in 2020 were €24 million, which is a reduction of €35 million compared with 2019. This difference is attributable to the substantial investment in our property at Nijverheidsweg in Utrecht in 2019 in accordance with our strategic real estate plan. Limited additional investments in the construction of the Stedin Telecom Network were also made in 2020.

Investment plan

All of the grid managers prepared an investment plan for the first time in 2020. The investment plan is intended to replace the Quality and Capacity Documents, which were previously drawn up every two years for the Netherlands Authority for Consumers and Markets (ACM). The Investment Plan 2022-2022 sets out the expansion and replacement capital expenditure planned for the electricity and gas grids. The investment plan details how we will ensure sufficient capacity for the distribution of electricity and gas in the next three years and how these distribution services will be provided safely. The plan was made available for consultation for four weeks, to give the opportunity for comments on the proposed investments. The consultation took place as follows:

- The plan was published on the website with the possibility to submit opinions.

- Dialogue took place with five municipalities (Rotterdam, The Hague, Utrecht, Dordrecht and Zoetermeer).

- The remaining municipalities were actively informed about the publication of the investment plan.

- Dialogue took place with national stakeholders under the umbrella of Netbeheer Nederland to provide further information on the purpose of the investment plans. This was undertaken with VEMW (the centre of expertise and organisation representing the interests of commercial users of energy and water in the Netherlands), the Association of Provincial Authorities (IPO), the Association of Netherlands Municipalities (VNG), Holland Solar, the Netherlands WindEnergy Association (NWEA) and the NVDE Netherlands sustainable energy association, for example.

- The 2020-2022 Investment Plan was incorporated in the Regional Energy Strategy for Zeeland (principal stakeholders).

- Selected customers of Enduris were also contacted.

In total, eight opinions were submitted to Stedin and four to Enduris. The submitted opinions from the consultation and our response to them were added to the investment plan. The plan was also submitted to the Netherlands Authority for Consumers and Markets (ACM). Following assessment by the ACM, the final investment plan was adopted and published on 1 October 2020.

As not all the regional energy transition plans were available for the 2020-2022 investment plan in Stedin's service area, recognised regional and national available sources, such as calculations of the effects by the PBL Netherlands Environmental Assessment Agency, applications under the Sustainable Energy Generation Incentive (SDE+) scheme and public and private property developments, were used for the investment plan.

Future-proof energy supply for Utrecht Science Park

Utrecht Science Park is the largest science park in the Netherlands and houses hospitals, universities of applied sciences, Utrecht University and various research institutions. It accommodates more than 27,00 staff members and 51,000 students. The science park is attracting an increasing number of centres of expertise, such as the Netherlands National Institute for Public Health and the Environment (RIVM). As this development is accompanied by a rising demand for energy, Stedin laid a third 50 kV connection to Utrecht Science Park in 2020. A third transformer will be added in 2021 to expand the energy supply capacity. Once the work is completed, the science park will be assured of a reliable energy supply and sufficient capacity.

Main investment results

The investments in the working area of Stedin and Enduris that stood out the most in 2020 were made for grid reinforcement or with the aim of facilitating maximum utilisation of grid capacity. Further information on these investments can be found in the section on 'Facilitating the energy transition'. The three projects concerned are advance investment in a main distribution station in Borsele, Station Europoort in Rotterdam and the expansion of five transformer stations in Zoetermeer.

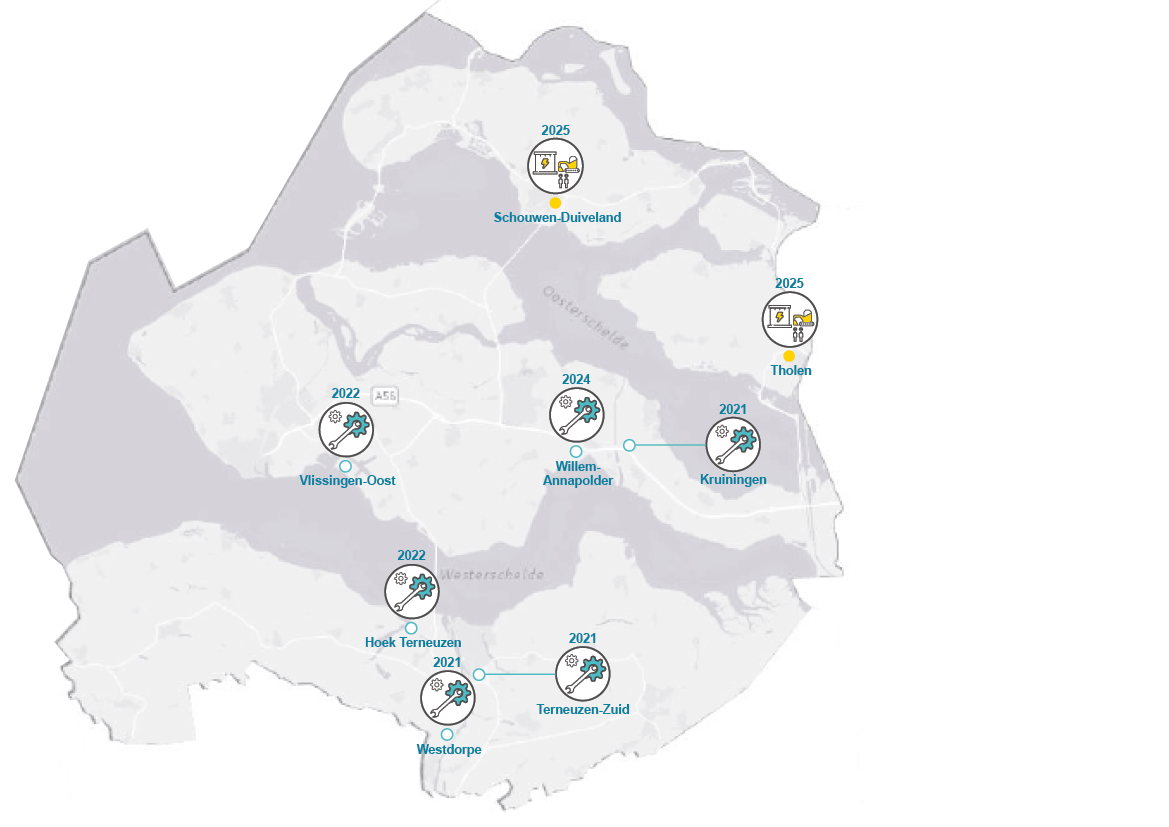

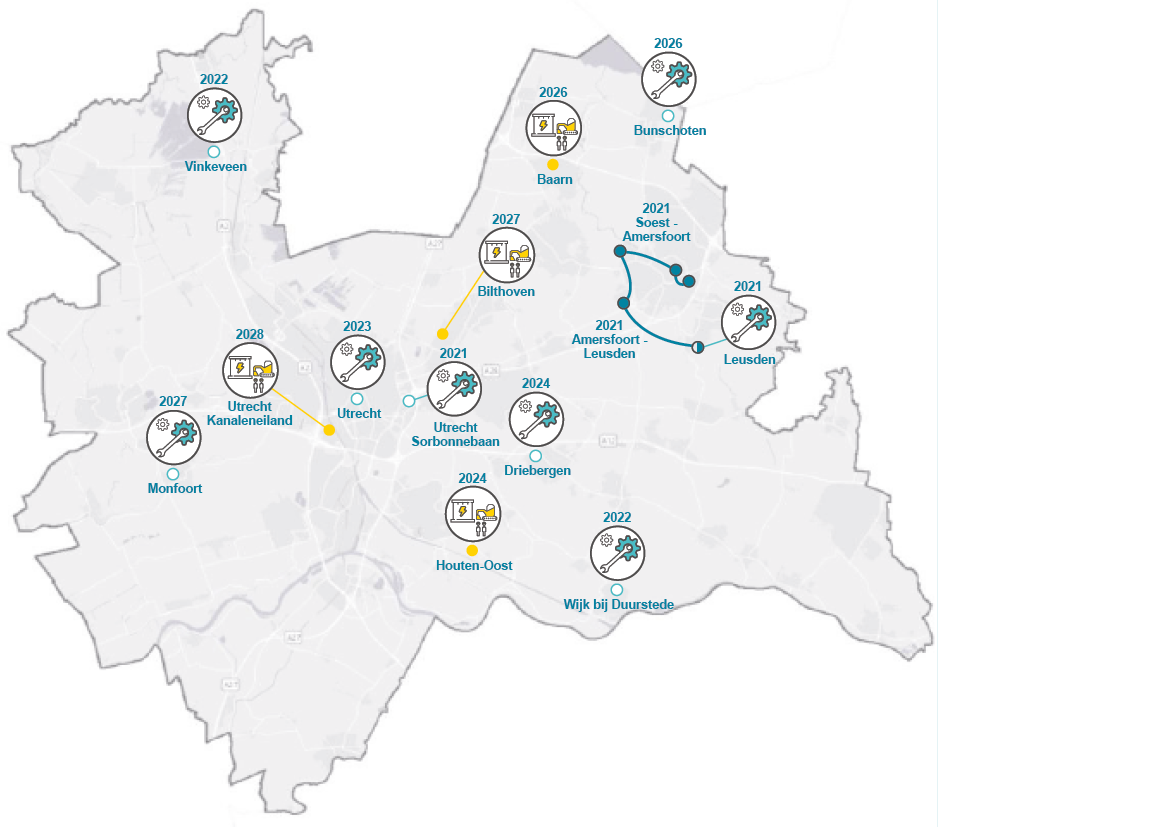

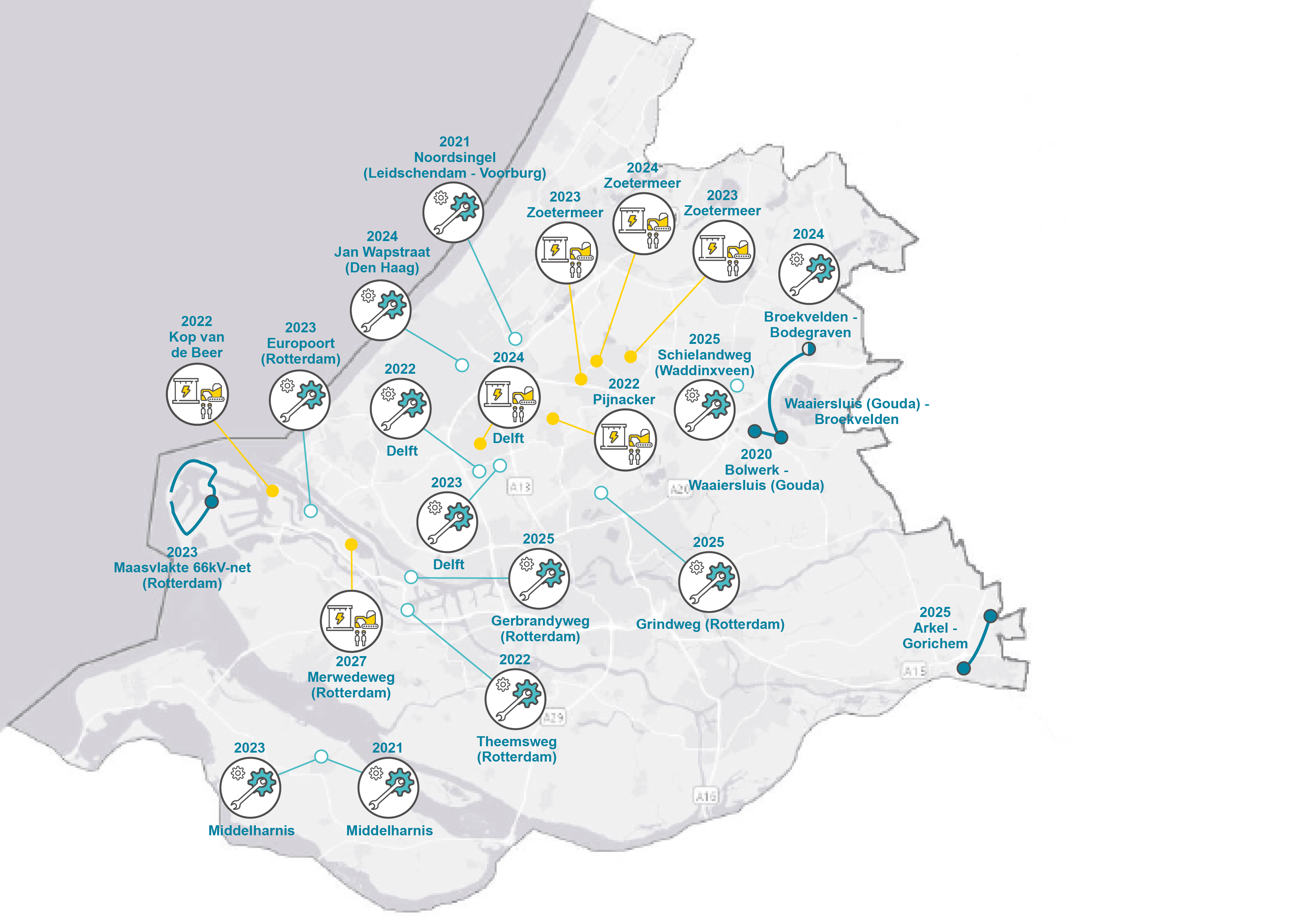

To ensure continuing support in society for the substantial task inherent in the energy transition, the grid managers face the major challenge of becoming increasingly transparent and of constructing future electricity stations or carrying out grid reinforcements. The maps on the following pages for the provinces of Utrecht, Zeeland and South Holland show the planned investments in electricity for stations and connections (>25 kV) that will be undertaken or commenced in the period 2020-2022. The expected year of completion is indicated for each project. The maps are focused on grid expansion.

Planned investments in electricity for stations and connections (>25 kV) undertaken or commenced in 2020-2022.

What is the average cost of a station in terms of money, time and space?

A station covers between 200 and 10,000 m2. It takes between 2.5 and 5 years to construct a station, at a cost of €1.5 million to €10 million, excluding land purchase costs. Installing the connection takes between 6 months and 3 years, at a rough estimate, and costs €100 to €1,000 per metre.

Stedin will invest €784 million in expanding the electricity grid in the period 2020-2022. Enduris will invest €86.9 million. Expansion capital expenditure accounts for 41-48% of the total investments that will be made. In 2021, we will invest €15,549,000 in the province of South Holland and €25,440,000 in the province of Utrecht in capacity expansions, which will be technically ready in the same year. This excludes DNWG, Telecom, NetVerder and other Stedin investments.

|